See post Shaping Hazards before mixing polyester resins.

Taping

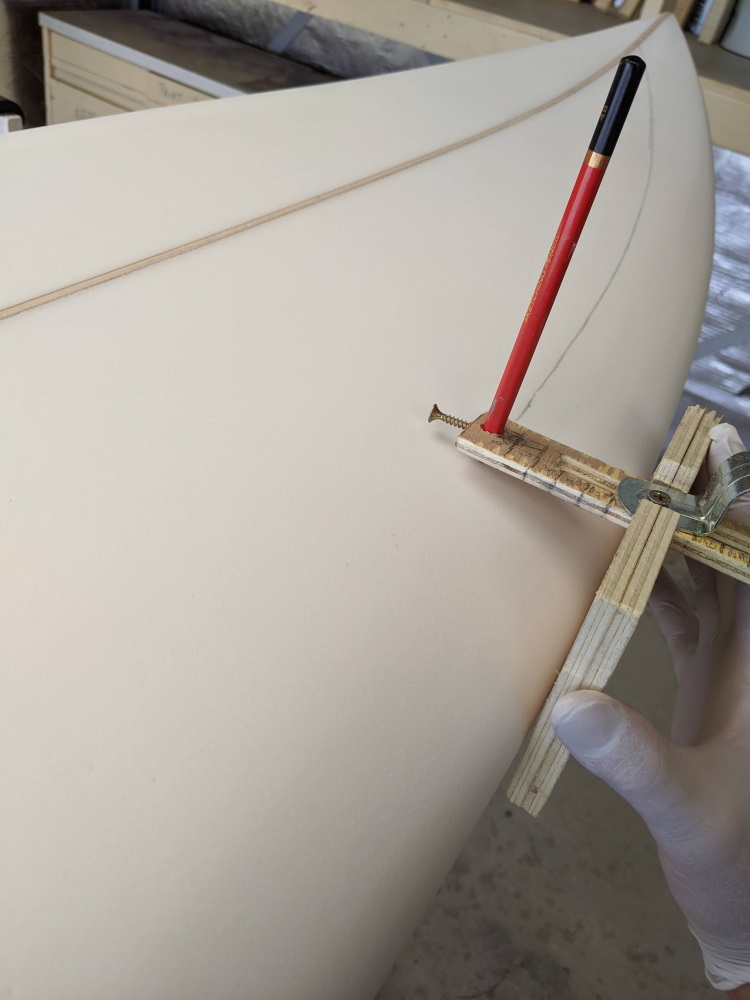

Using a rail scribe set to 60mm, run a circuit around the board. This will be your outline for taping off.

Using high-temp masking tape, line the board with protective layers of tape, until the deck area is completely covered.

The board is ready to be turned over for glassing of the bottom side.

Glassing schedule

-

Laminate bottom of board

- Sand the rail laminate flush to the deck

-

Laminate top of board

- Sand the rail laminate flat to the base

-

Hot coat bottom of board

-

Hot coat top of board

-

Sand

-

Wet sand

-

Buff and polish

Lamination

Firstly, Clean board with compressed air, to get rid of any spots of dust or dirt.

Cutting the fibre to suit

For this single fin board, I will be using a canary yellow pigment and running a cut-lap of glass around the board. I will cut a layer of 6 oz cloth for the V-shape around the finbox (As pictured)

Bringing the cloth approx. 4 inches past the fin box, cut the section following the shape of the tail. Then, fold the cloth in half along the stringer.

Folding the cloth in half allows you to cut an equally shaped finbox patch.

Next, drag a layer of 4oz cloth over the entire board.

Carefully cut a lap around the board, leaving a 'curtain' around 100mm long.

Continually check to make sure the curtain will overlap your tape job underneath the board on the deck side.

When cutting the cloth around the tail, cut 3 lines, 1 in line with the stringer, and the other 2 in line with the outer edge of the board, where the rounded section becomes straight. Cut the cloth at the nose in one straight line to the stringer.

Laminate

Mixing your resin

When mixing your resin, you can choose to tint it with any colour. I used a yellow pigment, mixing my desired concentration into a small cup of resin. After mixing the paste well, add the contents of the cup to 2l of laminate resin. When you are ready to glass, place 5-10ml (depending on room temperature) of MEKP hardner into the resin and mix thoroughly.

Applying first layer of resin

Pour a generous amount down the length of the stringer. Press the resin into the cloth using long top-bottom strokes with a squeedgee. Allow the resin to seep over the sides onto the curtain, being careful to catch any excess in your tub.

After adequately soaking the curtain, begin to comb it underneath the board, starting from the centre and working towards the tail, then again from the centre towards the nose. Work the tail and nose curtains until they are neatly pressed into the foam.

Continually work the resin until it becomes tacky, ensuring that there are no drops or discolourations that have gone by under the radar.

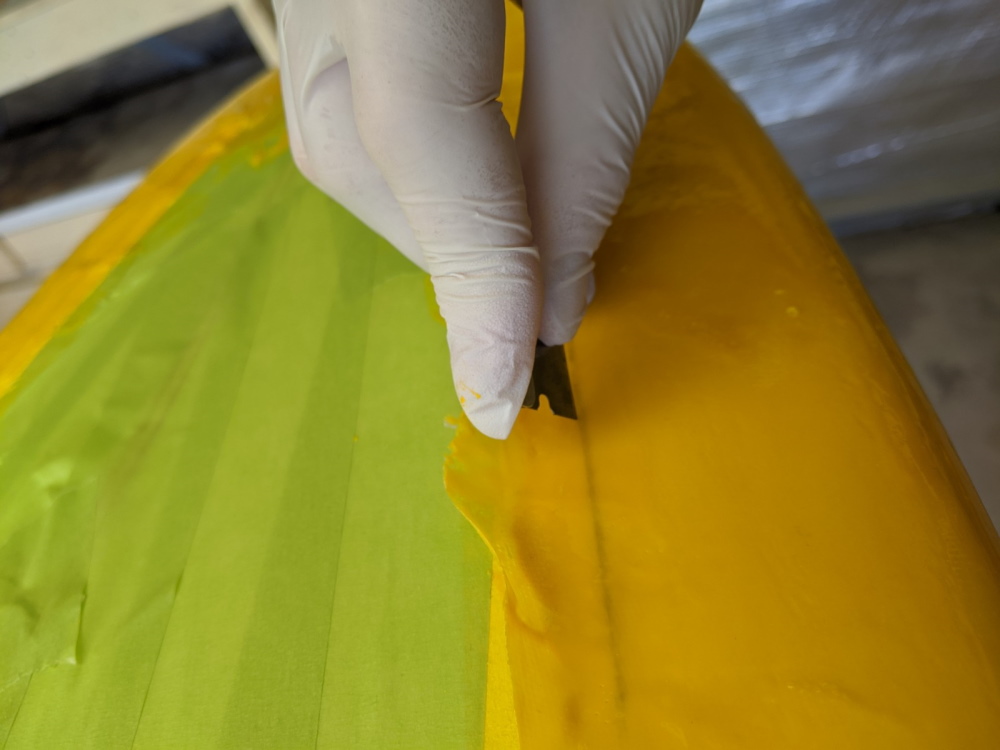

Leave the board to cure overnight. When you return, carefully run a blade around the tape line on the deck, you should do this delicately. A good indication that you are not too deep is the sound of the glass parting with only slight pressure on the blade. Peel off the deck patch.

Give the bottom and rails a sand to make the raised cutlap flush with the deck of the board.

Laminating the deck

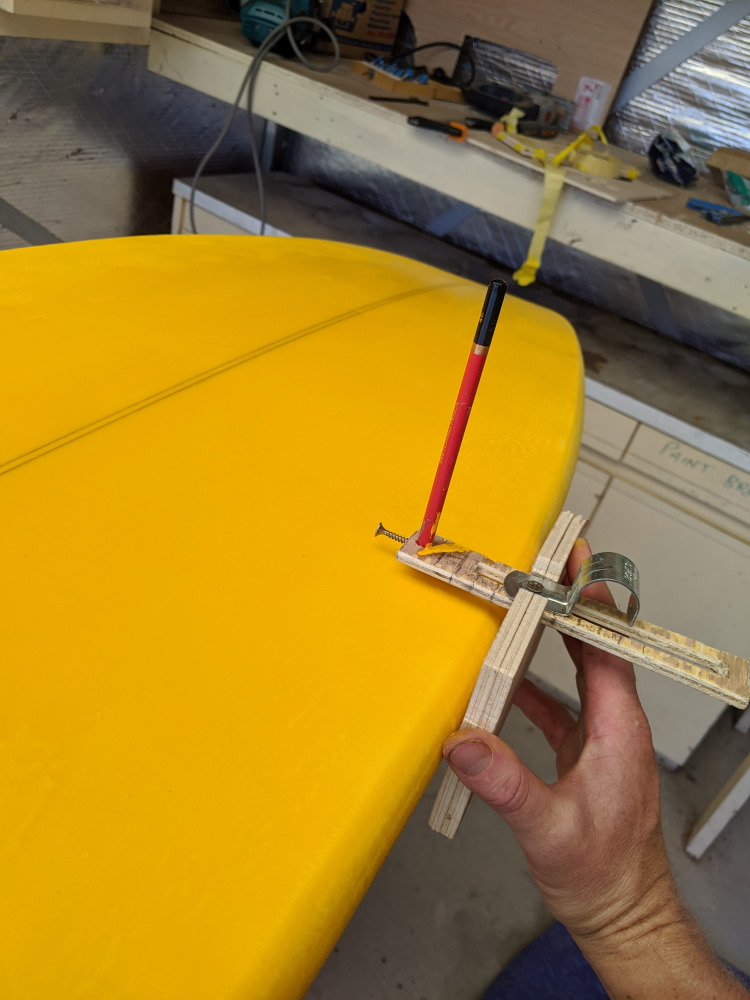

This is essentially the same as the previous step. Assuming that you've already routed and installed the leash plug. Run a lap around the laminated base. This time I measured out a cut-lap of 50mm.

Tape the base

Using the same technique in laminating the base, press your resin mixture into the foam and comb the glass over the tape job. Once again, allow the resin to cure overnight before cutting the lap with a sharp blade.

Preparing the laminate and finbox.

When prep sanding for the hot coat, ensure you have removed any burrs or ridges left over from the cured laminate. Sand the finbox flat to the base of the board, being careful not to remove too much laminate.